What makes quality wool? That’s for sure the first thing you really want to know when you are starting to create a tailored suit. “Is it a 160s wool fabric better than a super 100s?” and “What does it mean 100s?” are our clients’ most common questions. Well, answers depend on various aspects and on your needs. Let’s start from basics.

Wool fibers

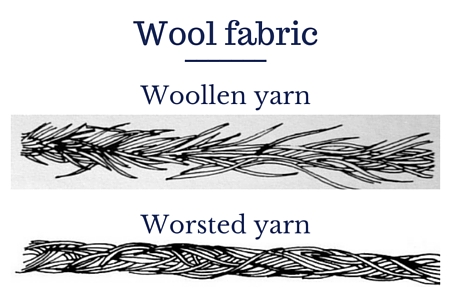

A wool fabric is basically an elaborate twist of fibers and their properties determine the quality, value and use of the fabric. You may have seen some of the wool fabrics described as worsted and some of them described as woollen. These are just the two most important types of wool (long staple vs short staple) spinned and weaved in different ways, resulting in a different look and feel.

The majority of men’s suits are made from worsted wool, which refers to a specific spinning process that separates long and strong fibers from the others. Worsted wool fabrics are made from long fibres which all lie parallel, the natural crimp of the wool is removed, and they form a very tight, hard yarn. What’s the result? Worsted wool looks smoother and lighter; woollen wool is much hairier and warmer, because it is full of air among the short fibers which acts as insulation.

The majority of men’s suits are made from worsted wool, which refers to a specific spinning process that separates long and strong fibers from the others. Worsted wool fabrics are made from long fibres which all lie parallel, the natural crimp of the wool is removed, and they form a very tight, hard yarn. What’s the result? Worsted wool looks smoother and lighter; woollen wool is much hairier and warmer, because it is full of air among the short fibers which acts as insulation.

But why we’re talking about fibers? This is really important if you want to know what’s that number followed by “S” on the label of wool suits.

Fabric fineness

The S numbers for worsted fine wool fabrics are intended to state the fineness of the wool fiber used in the product, as measured in micrometres. The origin of this measurement system comes from the British Bradford table, representing the number of 560 yard yarns which can be produced with a pound of wool. The S number, as you know, appears as a plural with an ” s ” or ” ‘s ” following the number, such as 100s or 100’s, and comes from the term hanks.

The S numbers for worsted fine wool fabrics are intended to state the fineness of the wool fiber used in the product, as measured in micrometres. The origin of this measurement system comes from the British Bradford table, representing the number of 560 yard yarns which can be produced with a pound of wool. The S number, as you know, appears as a plural with an ” s ” or ” ‘s ” following the number, such as 100s or 100’s, and comes from the term hanks.

Generally speaking, the higher the fineness number goes, the lighter and finer the cloth produced will be. 100s, for example, are perfectly good wools and make fine, sturdy suits for every day, while Super 130s are edging into more of a luxurious, smooth texture. A Super 160 will be incredibly fine and smooth, and anything higher is generally considered to be extremely precious. Ultrafine wools are used to create lightweight fabrics: 250g/m, 220g/m or less. The downside is that over 160’s fabrics will be quite delicate and will require most careful treatments.

The S number often is used in conjunction with the word “super” which originally meant the best wool, can not be used for fabrics made from wool blended with fibers such as mohair and cashmere and also with silk. For these fabrics, the word Super is not permitted. If we want to describe a blended fabric fineness we have to use two separate number, one for each material if possible.

The S number often is used in conjunction with the word “super” which originally meant the best wool, can not be used for fabrics made from wool blended with fibers such as mohair and cashmere and also with silk. For these fabrics, the word Super is not permitted. If we want to describe a blended fabric fineness we have to use two separate number, one for each material if possible.

Fiber fineness is certainly one of the factors determining the quality and performance of a wool product, but it is not the only one. Quality of wool also depends on some things such as the fiber length, scale structure, color, and cleanliness. The most sought after wool is very thin in diameter (10 to 20 micrometers), long in length (at least 2 to 5 inches), and the fibers themselves are free from defects.

That said, choosing the right fabric for every season and occasion, surely depends also on weight.

Fabric weight

The weight of wool is in fact the other frequently-used metric, and the number always refers to the weight of a single yard of material. Traditional “four-season” wools (which are generally considered wearable from fall through spring in temperate climates) usually weight between 240 and 270. Summer wool fabrics are below 240, and winter ones are up to 270 gr.. This works for wool fabrics only. A linen fabric could weights 390 but its breathability and strength make it one of the best summer fabrics.

The weight of wool is in fact the other frequently-used metric, and the number always refers to the weight of a single yard of material. Traditional “four-season” wools (which are generally considered wearable from fall through spring in temperate climates) usually weight between 240 and 270. Summer wool fabrics are below 240, and winter ones are up to 270 gr.. This works for wool fabrics only. A linen fabric could weights 390 but its breathability and strength make it one of the best summer fabrics.

Thanks to its properties of resilience, durability, physical attractiveness, insulating ability, and comfort wool fabric continues to be the first choice of every well-dressed gentleman.

There’s something better than wool, in your opinion?